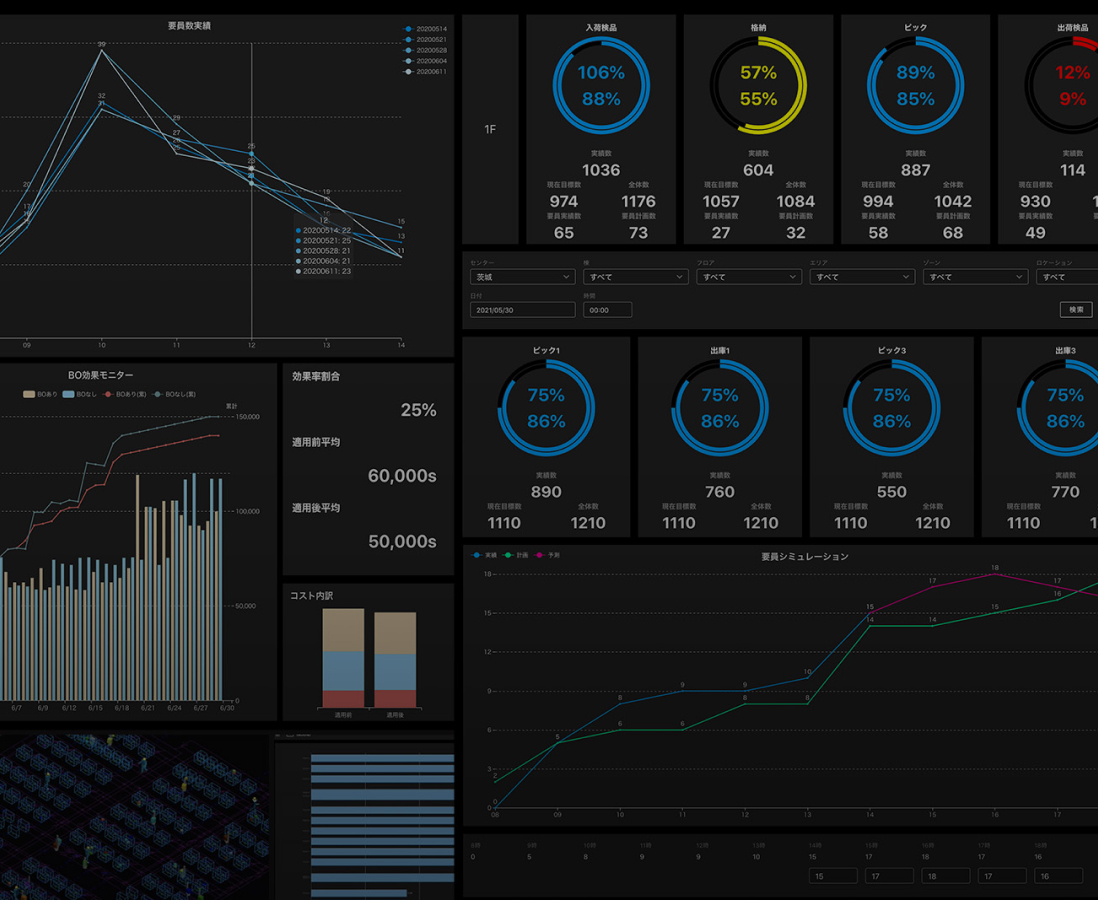

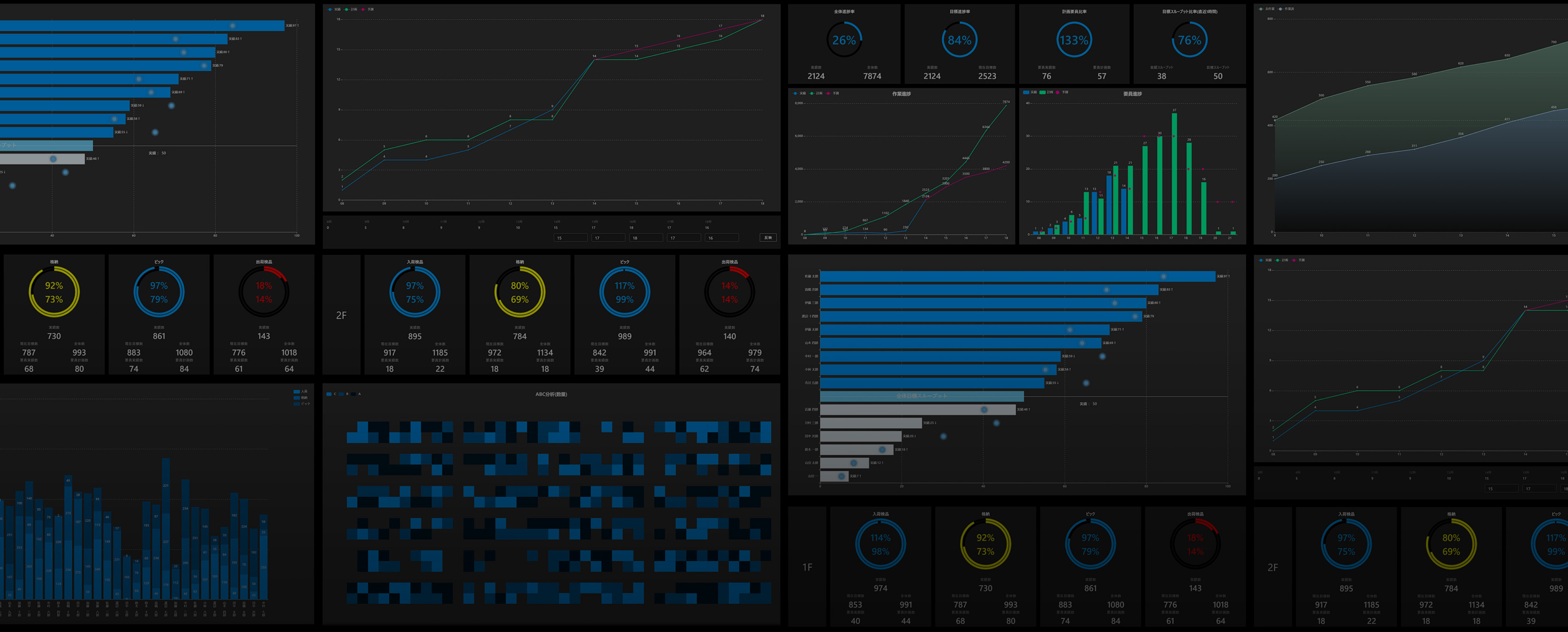

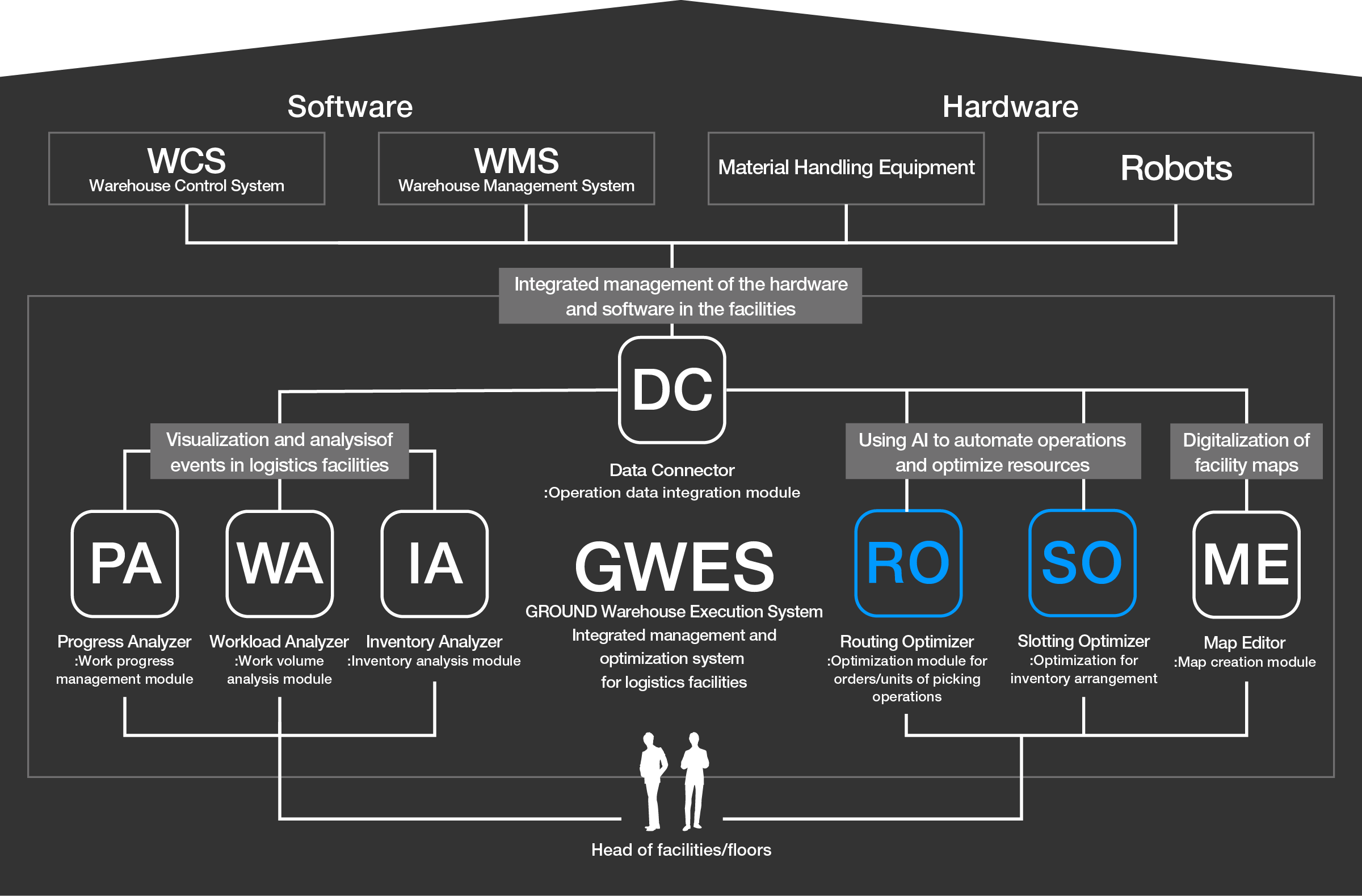

Integrated management and optimization system for logistics facilities

Automation of operations and optimization of resources by GWES

Overview

When the optimization of logistics facilities is considered, the improvement of the efficiency of all of the facilities' work processes and inventory storage through the continual review of product inventory management is an extremely important task.

However, the operations of logistics facilities today are increasingly complicated and every year the services required of them become more sophisticated reflecting changes in the macro environment and consumer trends. Therefore, these facilities are not operated mainly by humans. Instead, multiple softwares, robots, material-handling equipment, and similar devices have been introduced in these facilities handling a huge variety of products. This has made it difficult to manage the facilities using the previous methods, where decisions are made using human experience and intuition.

GWES, the integrated management and optimization system for logistics facilities, has two work automation and resource optimization modules that help business operators solve the above issues.

-

Module for optimizing orders/units of picking operations

Routing Optimizer

-

Module for optimizing inventory arrangement

Slotting Optimizer

Note: It is possible to use only one of the modules and to purchase the modules individually, depending on the purposes or issues of the specific customer.

Features

Improving the throughput of the picking process by analyzing and sorting product orders

GWES automatically controls picking order by analyzing information about orders that have been placed and consolidating orders for products that are stored close to each other, based on the load capacity of each wheeled platform (forklifts, robots, roll box pallets, etc.). This reduces the distance traveled by workers in the picking process and helps improve overall throughput.

Suggesting inventory arrangements that improve work efficiency and storage efficiency

GWES suggests locations for inventory products which simultaneously improves the efficiency of the picking process and the efficiency of product storage by simultaneously analyzing a large number of parameters that are difficult for humans to calculate.