Ranger™ GTP

Note: Product name changed by the manufacturer (formerly known as Butler)

Overview

Combining a robot that moves across logistics facilities' floors and a dedicated portable shelf, this system moves the entire shelf to the worker with the goods stored in it. It significantly reduces distances walked by workers to pick and store goods, thus reducing the labor required by logistics facilities.

History of Use

-

-

This system has been introduced by more than 70 companies in 16 countries, including major overseas apparel companies and retailers listed in Fortune 500, as well as TRUSCO Nakayama Corporation, Daiwa House Industry Co., Ltd. and other major companies in Japan. Ranger™ GTP automates logistics and fulfillment operations and reduces the labor that is required on a global scale.

Features

Ranger™ GTP is an innovative Goods-to-Person (GTP) robot solution that automates the picking and storing operations of logistics facilities, ensuring increased throughput, accuracy, and productivity.

The robot communicates with GreyMatter, control software in real-time, to be always up-to-date to receive the latest work instructions. This feature prioritizes operations in real time to maximize the efficiency of acceptance and delivery. It is a unique feature that is available with no other GTP product.

The latest model (V3.0), which will soon be launched in Japan, features a compact body that is an approx. 25% reduction of the robot's overall height. This enables a higher density of 2D code labels affixed on the floor, ensuring higher storage efficiency than the previous model. Further, the new model also boasts increased stability. This means that floor leveling work is not necessary for the introduction of this model even if the floor would have needed to be leveled for the introduction of the previous model.

Advantages and Effects

-

Labor-reducing robot

Ranger™ GTP does picking and storing operations for human workers, reducing the labor required by logistics facilities.

-

Higher storage efficiency

Dedicated shelves can be placed close to each other, increasing storage efficiency.

-

Reduction of work errors

The station (PPS) for picking and storing operations has a projector that shines light on the dedicated shelf to enable the identification of the goods to be picked, minimizing errors.

-

Reduction of work hours

Ranger™ GTP improves the throughput of acceptance and delivery operations, enabling work to be finished earlier.

Product Specifications and Environment

(including power supply and Wi-Fi compatibility)

|

Ranger™ GTP (M)  |

Ranger™ GTP (XL)  |

||

| Dimensions and weight | Dimensions | 979 x 700 x 285mm | |

| Weight | 215kg | ||

| Operating environment | Operating temperature | 0° - 55℃ | |

| Operating relative humidity | 30% to 95% (no condensation) | ||

| Floor materials | For use on standard concrete floors without epoxy resins or surface hardeners Planeness: 7.5 mm Inclination: 1.5 degrees Step height: 5 mm Gap 30mm |

||

| Performance | Max. Load (including MSU) |

600 kg | 1600 kg |

| Max. speed | 1.2 m/s | 1.0 m/s | |

| Battery | Battery | Lithium ion battery, 52V, 40Ah | Lithium ion battery, 52V, 120Ah |

| Operating time | 8 hours | 6 to 8 hours | |

| Charging | Automatic charging The algorithm run by GreyMatter, the AI-based platform from GreyOrange, enables 24/7 operations. |

||

| Coordinated solutions Communications Stability |

Components | Shelf dedicated for accessories (MSU), multi-purpose station, smart chargers | |

| Coordinated solutions (optional) |

Vertical conveyor (vertilator) Wide selection of material handling equipment |

Vertical conveyor (vertilator) Wide selection of material handling equipment Accessories compatible with Ranger GTP |

|

| Communications | Wi-FI(IEEE 802.11 ac, 5GHz) | ||

| Safety features | Bi-directional obstacle detection system with infrared sensors detects objects as small as around 60 mm in diameter. Minimum distance from Ranger™ GTP to obstacle: 680 mm with Ranger™ GTP (M)/ 1,000 mm with Ranger™ GTP (XL) Two emergency stop switches and bi-directional bumpers for additional safety, fire and earthquake response. |

||

-

Please feel free to inquire about robot solutions from GROUND

-

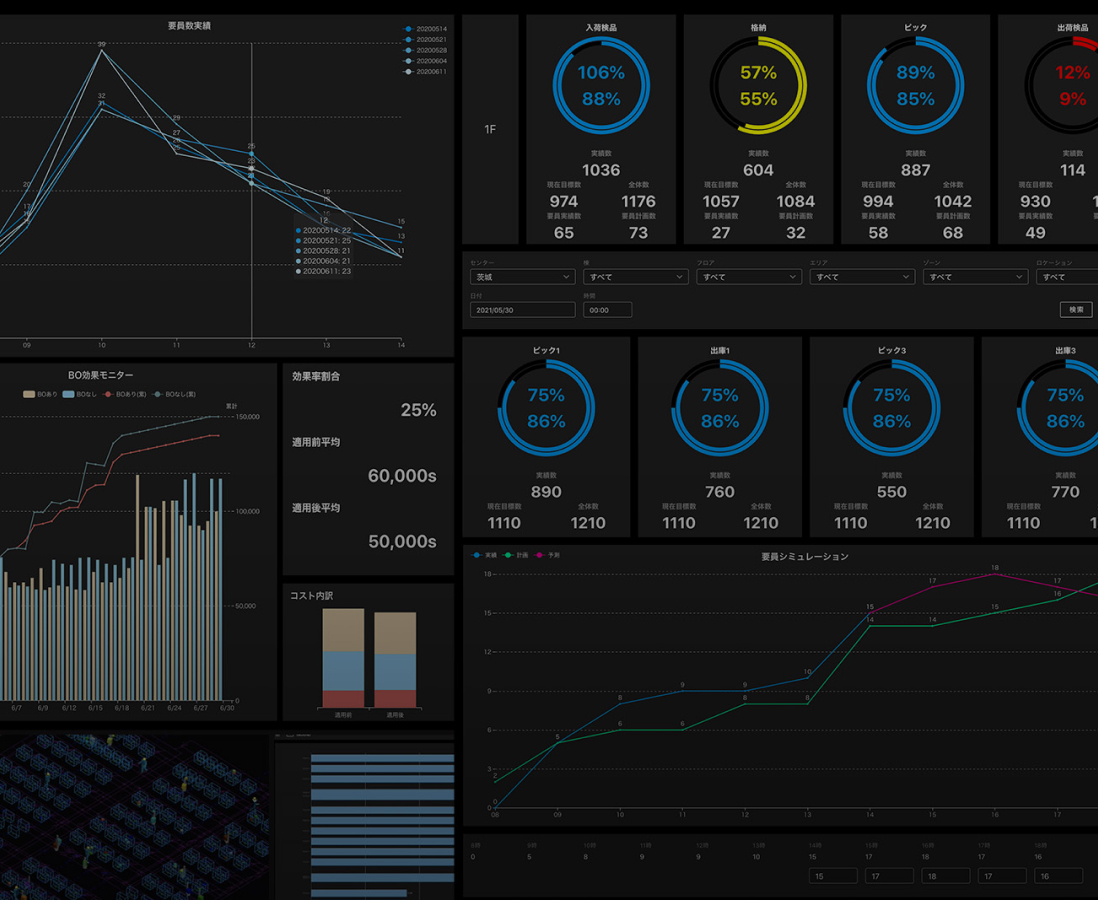

GWES - Integrated management and optimization system for logistics facilities using AI