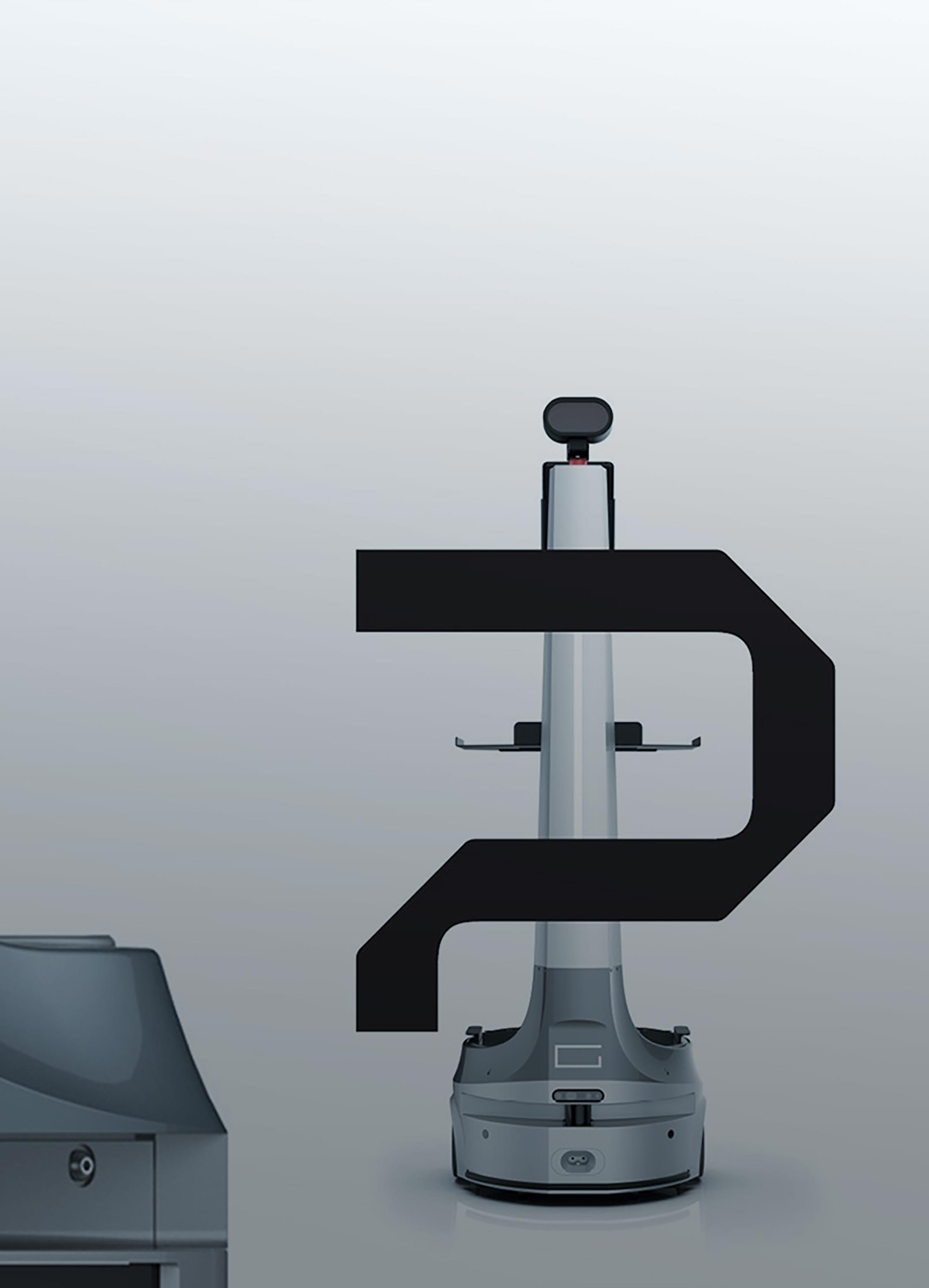

PEER Series

Overview

-

The PEER series is an Autonomous Mobile Robot (AMR) developed by GROUND in collaboration with a Chinese robot manufacturer.

PEER supports picking operations in logistics facilities by collaborating with staff. PEER is equipped with a technology for them to move autonomously.

Main Effects

-

Improving Productivity, Saving Labor and Manpower

Picking area is divided into several zones and one staff is in charge of one zone. By allocating multiple PEER’s to a single staff, productivity gets improved by the equivalent of several staffs. By reducing the time required for staff to travel and to find goods, PEER contributes to labor and manpower savings.

-

Improving Picking Accuracy

Picking instructions are provided by images on a tablet, improving the picking accuracy of staff and reducing human error.

In addition, “PEER SpeeMa+™”, with an RFID reader having automatic recognition technology, brings picking error occurrences close to zero.

Product Lineup

PEER ST

PEER ST PEER ST SpeeMa+™

PEER ST SpeeMa+™ PEER 100

PEER 100Main Features and Advantages

-

Easy to Introduce

The PEER series is highly versatile and does not require large-scale installation work, so it can be introduced quickly without interrupting logistics facility operations.

The PEER series can be easily expanded or relocated, and supports the promotion of automation while taking advantage of existing layouts and work operations. -

High-precision Autonomous Operation

Unlike AGVs, which require derivatives, and GTPs, which require dedicated racks, the PEER series can travel autonomously without setting route information. SLAM technology integrates information from cameras and lasers to enable the robot itself to acquire positional information in real-time and select the optimal route that avoids obstacles in the path.

-

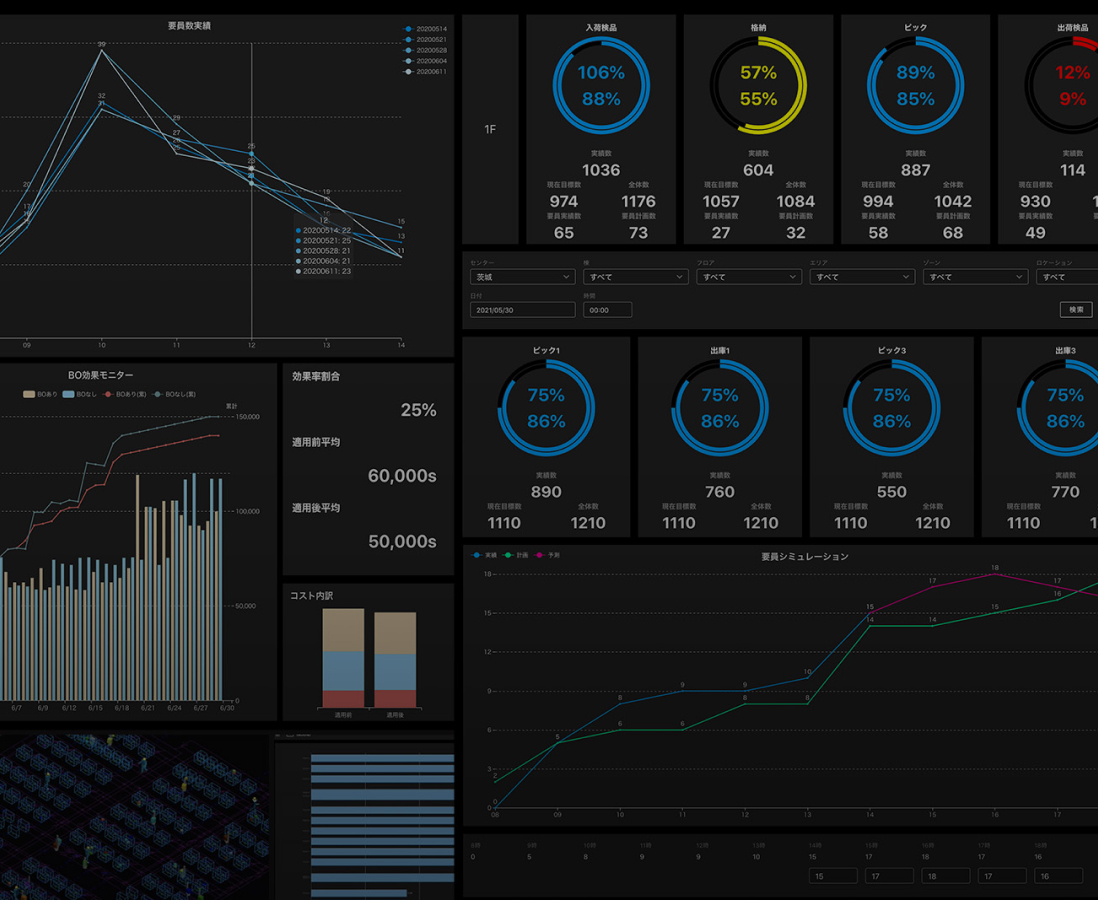

Flexible Data Linkage

The PEER series can be interfaced with WMS. Our dedicated converter can sort orders for efficient picks. On the other hand, to minimize WMS modifications and reduce implementation time and costs, the PEER series can also be implemented without WMS integration.

-

High Operability

The PEER series' high-visibility tablet screen enables high productivity regardless of staff experience and skill level. It also contributes to efficient training and education of staff.